Castello, Spain - Recognizing that production

of femtosecond lasers for micromachining is still slow and expensive, researchers

in the GROC Optics Group at James I University have developed an original

parallel-processing technique that could multiply their production capacity,

thus improving their performance, reducing the time and cost of

manufacturing, and optimizing the use of laser energy. Jesus Lancis, director

of the GROC Optics Group, highlights that the progress achieved "will

significantly improve the performance of this technology because it will

enable to process the material simultaneously in several locations and,

besides, without losing accuracy. Both facts are key to increase the

production rate of laser technology, thus lowering manufacturing costs and

allowing their gradual introduction into various sectors which used more

traditional production mechanisms hitherto."

|

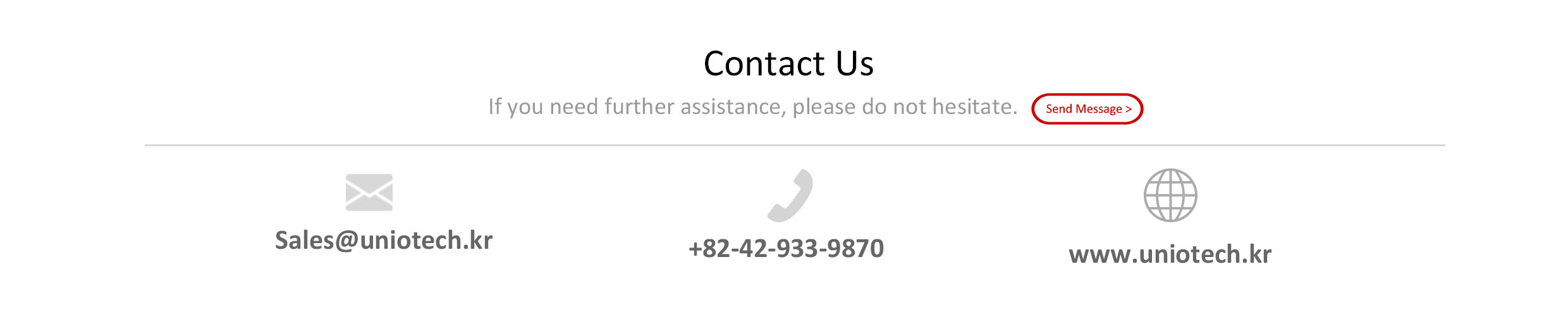

Jesus Lancis of the Grup d'Optica de Castello (GROC). (All

photos courtesy of Alex Perez)

|

The parallel-processing technique the researchers developed enables splitting

the laser beam into a series of multiple beams through what is called a "compensated

dispersion module." It has already proved its effectiveness to

simultaneously generate 52 blind holes measuring less than 5μm in diameter on

a stainless steel sample. "This research shows that we can increase

production speed by a factor of 52, or even 100, without losing quality, with

the change of system parameters," explains Gladys Minguez-Vega, a

researcher in the GROC Optics Group.

|

|

JGladys Minguez-Vega of the Grup d'Optica de Castello

(GROC).

|

Pulsed femtosecond laser technology has provided a greater precision and

quality, says Mínguez-Vega. "These lasers are being used, for example,

in some surgical operations for less invasive, more localized, and precise

cuts, or in the development of micromachining in all types of materials,

including the biodegradable ones. With so short exposure times and with such

a high energetic charge, femtosecond lasers also prevent heat from spreading

beyond the point to which it is addressed, even allowing their use for

cutting explosives," she adds. The fact that energy is so concentrated

means that it has to be softened. "If you spent all this energy, you

will deposit so much energy that you would end up causing damage to the

material. To avoid this, we use some filters that reduce light to the right

energy," Mínguez-Vega explains. The matrix the researchers developed

allows splitting the beam and multiplying the points of light while reducing

the energy of each one of them. "Currently, for micromachining a piece with

a femtosecond laser, we have to move the laser or the material to scan it, so

production has to be performed point to point," she adds. The matrix

they developed divides beams and keeps their effectiveness, enabling

micromachining of dozens of different pieces simultaneously and multiplying

by hundred the speed of the system with the subsequent cost reduction.

|

Grup d'Òptica de Castelló (GROC).

|

The fact that energy is so concentrated means that it has to be softened. "If

you spent all this energy, you will deposit so much energy that you would end

up causing damage to the material. To avoid this, we use some filters that

reduce light to the right energy," Mínguez-Vega explains. The matrix the

researchers developed allows splitting the beam and multiplying the points of

light while reducing the energy of each one of them. "Currently, for

micromachining a piece with a femtosecond laser, we have to move the laser or

the material to scan it, so production has to be performed point to point,"

she adds. The matrix they developed divides beams and keeps their

effectiveness, enabling micromachining of dozens of different pieces

simultaneously and multiplying by hundred the speed of the system with the

subsequent cost reduction.

Full details of the work appear in the journal Optics Express; for more information,

http://dx.doi.org/10.1364/OE.21.031830.

|